[vc_row][vc_column][vc_column_text]

Making the Case for High Flow Biofiltration Systems

We all know the history of Low Impact Development (LID). Developed in Prince George’s County, Maryland in the early ’90s, adopted throughout the Chesapeake Bay, gradually adopted in the Northwest and the Great Lakes and now picking up steam and moving coast to coast; it’s an important part of the upcoming post construction rulemaking and TMDL responses; and its rightfully recognized as a key piece to solving our water quality, volume and velocity woes and to meeting our sustainable development goals.

But it’s not all sunshine and rainbows. Those of us who are practitioners in the field of stormwater all know that problems exist with the dominant BMP used in LID design, bioretention/ biofiltration systems. Reasons for these problems abound. Over reliance on 20 year old design guidance, just plain bad soil media designs, inexplicable, but common lack of quality controls on soil media production and system installation, little or no field verification of performance and the list goes on and on. The end result is intolerably high failure rates; in some areas failure rates are as high as 50%, for this critically important BMP.

One key reason is that industry has lagged behind in commercializing bioretention solutions like it has for other Low Impact Development techniques like Water Harvesting Systems, Green Roofs and Porous Pavement, to name a few. This blog is a three part series based on my six years of experience with the design and construction of biofiltration systems, and what I have learned in the process. I’ll also talk about our quest to commercialize an inexpensive biofiltration solution that is far superior to traditional designs in terms of economics, reliability, volume control, and most importantly the water quality benefits, is ushering in a boom in ‘next generation’ LID solutions for stormwater.

Part One – The Economics

The economic incentives are far reaching for LID as a whole. The reduction in peak runoff allows us to greatly reduce detention pond requirements, avoiding the waste of valuable land. The use of integrated, multi-functional landscaping and drainage allows us tremendous storm sewer size and cost reductions and the inherent water quality benefits allow us to avoid the expense of sand filters and hydrodynamic separators, not to mention the high long term maintenance costs associated with such infrastructure.

These economic considerations are important. Houston, Texas, is a city riding the wave of a boom in LID-based projects, despite very high detention requirements and not a single regulation that requires LID’s use. Why? Because the economics of Low Impact Development are being maximized as a result of key jurisdictions in the region having resisted the urge to write prescriptive, design-based standards for LID within their development codes. Instead, they’ve set stringent performance-based standards and prescribed onsite verification requirements that require designers to exceed much of what’s being done around the country by building better bioretention/ biofiltration systems. This approach encourages innovation.

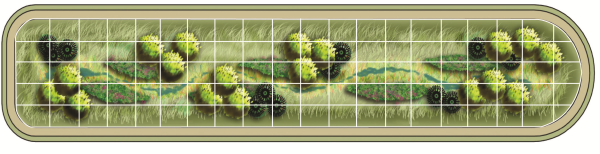

This effort to promote innovation rather than hinder it with well-intentioned, but often counterproductive design standards has allowed companies like Construction EcoServices and the engineers that they work with to foster a local stormwater industry based on economic benefits. In that environment they’ve come up with better and more efficient ways to manage stormwater with LID and it is high performance, high flow rate biofiltration media that’s made this possible. It offers us a smaller, safer, more reliable, more maintainable and more effective biofiltration systems than traditional slow flow rate systems.

Example:

Assume we have a five acre development, 4 acres being impervious and 1 acre pervious. Our runoff coefficient is .90 and .25, respectively, and we want to treat the first 1.5″ of runoff within 24 hours. In order to handle the water quality volume through a low flow biofiltration media made up of sand and organics which flows at 5″ per hour we would need approximately 3,553 SF of biofiltration media bed.

For this example we will assume a swale that is 12′ wide and 300′ long and 1′ deep. The costs break out like this:

3,533 SF of Biofiltration Bed using 5″ HR Media

Excavation:……………………………$2,700.00 (270 CF @ $10 CY)

Geotextile: ……………………………$800.00 (1.3 Rolls @ $500 Roll)

Perforated Pipe: …………………..$1,200.00 (300 LF @ $4 LF)

Aggregate: ……………………………$2,200.00 (12″ On All Sides of Perforated Pipe)

Engineered Media: ……………….$10,000.00 (1.5′ Deep at $50 CY)

Bark Mulch: ………………………….$266.00 (3″ Deep at $8 CY)

Labor: ………………………………….$3,000.00 (120 hours @ $25 Hour)

Total: …………………………………..$20,166.00 ($5,238 per acre of effective area)

Assume the same scenario, but use a media that flows at 100″ per hour and we only need 108 SF of biofiltration media bed and much less excavation, underdrain, and LID-specific plantings. As the cost breakout below indicates, we’ve created a dramatically lower cost system that not only lowers cost, but is far better on almost any level. This high flow system, which Construction EcoServices is installing throughout the Houston area and across Texas, also opens the door to all kinds of design flexibility. We can put these biofiltration systems in places bioretention/biofiltration couldn’t possibly be used. Better yet, we get a manufacturer that will provide verification of insitu performance and offers free maintenance for the first year at no additional charge.

108 SF of Biofiltration Bed using 100″ HR Media

Excavation:………………………………………….$110.00 (11 CY @ $10 CY)

FocalPoint Biofiltration System: ………….$13,500.00 (108 SF @ $125 SF)

Total:………………………………………………….$13,610.00 ($3,535 per acre of effective area)

(FocalPoint Biofiltration System includes the following components: underdrain, bridging stone, mesh, geotextile, high performance engineered media, mulch, labor & maintenance)[/vc_column_text][/vc_column][/vc_row]